Howey Tool – Dedicated to making the best ice, mixed and dry/comp picks.

Based in Southern Ontario, Howey Tool is a one-man company committed to making the best ice, mixed and dry/comp picks. We caught with Jeremy Howey, the owner of Howey Tool, and discussed climbing in the 90s, advanced metallurgy and his desire to make picks.

The team from Howey Tool testing new pics.

So, let’s start with basics. How did you get into rock and ice climbing?

Howey Tool: I started rock climbing in 1993 when I was 14. I learned from a friend who was lucky enough to get private climbing lessons and a rack (at 14!). Before long we were doing routes at Bon Echo and the Escarpment. I tried ice climbing in Canmore on a family ski trip in 1997.

By 1999, I finished assembling my rack. I was mainly climbing in the 5.10/5.11 trad range and some harder sport routes. It was during this time that I got more serious about ice climbing; I took a formal course with a guide in January 2001 in Canmore. I came back and climbed extensively in Ontario and Quebec. I particularly enjoyed the old Festiglace competitions in Pont-Rouge because they opened my eyes to extreme mixed climbing. During this time we put in two hard mixed routes on Irvine Creek in 2002.

Then in the spring of 2002 I smashed my ankle in a trad fall in the Red. My gear held and I didn’t deck, but I did hit a rock on the way down. I basically ripped my foot off without breaking the skin. I was climbing again the next season, but I dialed it back to moderate routes and climbed less frequently. Since the accident I also caught up with the rest of my life, got married and had three boys. I focused on backcountry skiing through this period.I’ve been climbing more hard ice and mixed again over the last few years.

By 1999, I finished assembling my rack. I was mainly climbing in the 5.10/5.11 trad range and some harder sport routes. It was during this time that I got more serious about ice climbing; I took a formal course with a guide in January 2001 in Canmore. I came back and climbed extensively in Ontario and Quebec. I particularly enjoyed the old Festiglace competitions in Pont-Rouge because they opened my eyes to extreme mixed climbing. During this time we put in two hard mixed routes on Irvine Creek in 2002.

Then in the spring of 2002 I smashed my ankle in a trad fall in the Red. My gear held and I didn’t deck, but I did hit a rock on the way down. I basically ripped my foot off without breaking the skin. I was climbing again the next season, but I dialed it back to moderate routes and climbed less frequently. Since the accident I also caught up with the rest of my life, got married and had three boys. I focused on backcountry skiing through this period.I’ve been climbing more hard ice and mixed again over the last few years.

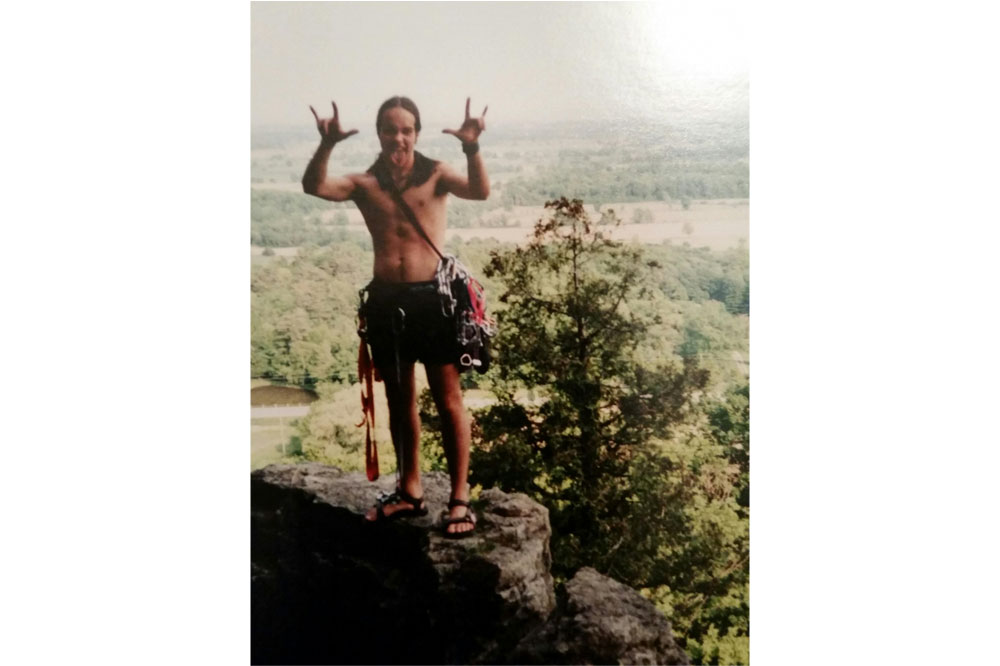

A younger Jeremy Howey enjoying the climbing in Southern Ontario.

Ok, now that we have that out of the way, can you tell us about your professional background?

Howey Tool: I am a machinist by trade. Part of the decision to do an apprenticeship was so I could climb and buy climbing gear, and not be a poor student like some of my friends. I apprenticed at Advance Metal, a tool and die shop where I learned to build complex progressive dies. Shortly after I wrote my ticket, I moved to the engineering side of the shop (2001). I started with CNC programming, wire EDM programming, 3D surfacing/solid modeling and die design. During this time I made climbing gear: pitons, hooks and a belay device. I worked at an injection molding machine builder as a tool designer from 2003 to 2008. Since then I’ve been a tool designer at an aerospace parts manufacturer. I’m responsible for the design, manufacture and procurement of all work-holding tooling and fixtures for the machining of complex hard metal and titanium parts. Recently I was promoted to Engineering Team Leader.

The Howey Tools Petzl Mixed pick (HOWT-PTZ-MIX).

So what prompted you to start making ice tool picks?

Howey Tool: The picks are something I’ve talked about with various people, usually when looking at our worn-out picks! I was pretty desperate for a new pair early last season. I saw what Krogonogi was doing and I came across the ‘Making picks’ thread on OntarioClimbing.com. I found it interesting and made some suggestions. Then instead of just talking about it, I started to work on the project. I had all the tools and material at my fingertips, so how could I resist! I outsource all the specialty processes to a small trusted group of Southern Ontarian companies.

The Howey Tools Petzl Ice pick (HOWT-PTZ-ICE).

And now a question for our gear geeks. Why did you choose the material you are using for your picks?

Howey Tool: Most stock picks are 4340 steel. The 300M (4340M) steel that I use is a forged block of aerospace-spec 4340. 300M is basically a finer grade of the same steel that stock picks are made from. The performance properties of the 300M are amazing. I am very familiar with the material as well as how it is processed and heat-treated. It is the best material that I know and have access to for making picks. It has an impressive ability to flex and snap back to exact straightness. We make many aircraft parts from this material: landing gear parts that take an impact are usually 300M. Looking at my picks after climbing a route with lots of torqueing and seeing them straight as an arrow always brings a smile to my face.

Can you tell us about the current picks you’re making?

Howey Tool: I use a new cloud-based mobile CAD application called OnShape. The material is sourced from a surplus cut-off of 300M that is saw cut and Blanchard ground (rotary surface ground) to 4mm. I start by water-jet cutting the profile and taper the picks to 3mm at the tip. Next, I hand sharpen and heat treat the picks. Once that’s completed, the picks are media blasted and go through a magnetic particle inspection process. I then apply a black oxide finish for corrosion resistance and layer of black paint on top of that.

The HOWT-PTZ-MIX is a true mixed pick tuned for optimum performance on ice with a 3mm taper, a sharpened top edge, a pick angle suited to steep mixed routes, and a steep hook below the tip. The aggressive stein-pull teeth follow an even radius creating solid contact. Each pick weighs 126g.

The HOWT-PTZ-ICE has a slightly opened-up pick angle (3°), improving the Petzl Nomic’s swing on straight-forward ice. This feature allows the Nomic climber to experience an interchangeable pick angle, similar to the handle switch on the Cassin X-Dream.

The HOWT-CXD-MIX is a pick for the Cassin X-Dream tools. It’s designed for steep mixed routes, sharpened and tapered for ice. It also allows for the use of the Petzl pick-weights. It has a low height at the tip giving it one of the smallest tip volumes I offer.

The HOWT-PTZ-MIX is a true mixed pick tuned for optimum performance on ice with a 3mm taper, a sharpened top edge, a pick angle suited to steep mixed routes, and a steep hook below the tip. The aggressive stein-pull teeth follow an even radius creating solid contact. Each pick weighs 126g.

The HOWT-PTZ-ICE has a slightly opened-up pick angle (3°), improving the Petzl Nomic’s swing on straight-forward ice. This feature allows the Nomic climber to experience an interchangeable pick angle, similar to the handle switch on the Cassin X-Dream.

The HOWT-CXD-MIX is a pick for the Cassin X-Dream tools. It’s designed for steep mixed routes, sharpened and tapered for ice. It also allows for the use of the Petzl pick-weights. It has a low height at the tip giving it one of the smallest tip volumes I offer.

The Howey Tools Cassin X-Dream Mixed pick (HOWT-CXD-MIX).

Are you doing anything particularly special during the manufacturing or finishing stages that you feel helps improve the performance of your picks?

Howey Tool: The overall sharpness and tune of all my picks is for optimum performance on ice. The extreme sharpness does make them slightly less durable than my previous versions on rock, but they now create very little displacement on ice. Most of the development I was doing early this season was for ice performance. I have been hand sharpening all the picks myself.

The high performance properties of 300M allow for a slightly harder heat treat than stock picks. My new picks are 46 HRC (Rockwell Hardness; higher is harder). This gives them better wear and a little less boing or bounce. In comparison, Petzl’s picks are 44-45 HRC, Black Diamond’s picks are 42 HRC and Cassin’s picks come in at 42 HRC. I did make picks as high as 48 HRC but dialed it back slightly.

The high performance properties of 300M allow for a slightly harder heat treat than stock picks. My new picks are 46 HRC (Rockwell Hardness; higher is harder). This gives them better wear and a little less boing or bounce. In comparison, Petzl’s picks are 44-45 HRC, Black Diamond’s picks are 42 HRC and Cassin’s picks come in at 42 HRC. I did make picks as high as 48 HRC but dialed it back slightly.

Comparing the Howey Tools HOWT-PTZ-MIX (background) to the Howey Tools HOWT-PTZ-ICE (foreground).

Did you involve anyone else during the design and testing process?

Howey Tool: I have had valuable input during the development stages from a few key climbers in Southern Ontario:

Daniel Martian has been very supportive of the project and was a motivational factor even prior to making the first set. We started this season with three different tunings on the HOWT-PTZ-MIX – the super-sharp tune for ice was the go-to consensus.

Stas Beskin has had a number of impressive ascents this season with my picks. His feedback has been very important in the development of the X-dream pick.

Andriy Kolos has also been very helpful. He sensed the extra hardness in the November development batch and suggested that I increase traction for spiking the top of the pick, pommel up while walking, resulting in the distinct top two Stein-pull teeth on the HOWT-PTZ-MIX pick.

Finally, Peter Hoang’s comments about the bounce-back he experienced on ice with last year’s picks pushed me to improve the picks’ performance on ice. Lately, he has inspired me to think about a super aggressive dry/comp pick.

Daniel Martian has been very supportive of the project and was a motivational factor even prior to making the first set. We started this season with three different tunings on the HOWT-PTZ-MIX – the super-sharp tune for ice was the go-to consensus.

Stas Beskin has had a number of impressive ascents this season with my picks. His feedback has been very important in the development of the X-dream pick.

Andriy Kolos has also been very helpful. He sensed the extra hardness in the November development batch and suggested that I increase traction for spiking the top of the pick, pommel up while walking, resulting in the distinct top two Stein-pull teeth on the HOWT-PTZ-MIX pick.

Finally, Peter Hoang’s comments about the bounce-back he experienced on ice with last year’s picks pushed me to improve the picks’ performance on ice. Lately, he has inspired me to think about a super aggressive dry/comp pick.

More product testing of the Howey Tools picks.

Speaking of testing, how are you testing the picks?

Howey Tool: For non-destructive testing, I’ve been doing magnetic particle inspection. This process is done on aerospace parts of the same material and detects any imperfections or flaws in the material.

For destructive testing, I’ve been breaking picks with a large pry bar and the tip of the pick in a vise 25mm from the tip. This hands-on method allows me to feel the pick break. I will bend a pick to the point of permanent deformation 4 times back and forth. Then the fifth bend I keep going until failure. I have broken the Petzl picks this way also.

I am now in the process of sending five picks of each model to Austria for UIAA accreditation testing, having settled on a long-term product design. I have simulated the UIAA tests and I’m very confident that they will pass.

For destructive testing, I’ve been breaking picks with a large pry bar and the tip of the pick in a vise 25mm from the tip. This hands-on method allows me to feel the pick break. I will bend a pick to the point of permanent deformation 4 times back and forth. Then the fifth bend I keep going until failure. I have broken the Petzl picks this way also.

I am now in the process of sending five picks of each model to Austria for UIAA accreditation testing, having settled on a long-term product design. I have simulated the UIAA tests and I’m very confident that they will pass.

Destructive testing ensures the quality and consistency of the Howey Tool picks.

From your site, it seems that the picks are currently only available for the Petzl Nomic, Quark, Ergo and Cassin X-Dream. Will you be expanding the line to serve other tool brands?

Howey Tool: Yes, I plan to add other brands, but first I would like to sell the existing models, have them pass testing and help prove that the business is viable. I would like to be a custom-pick provider as well as expand the number of picks I offer for other tool brands. Right now I’m working on a weld-on hammer and a drytool/comp pick.

A sneak peak of the new Howey Tool hammer.

Finally, do you have any upcoming ice or rock climbing trips?

Howey Tool: Nothing extravagant planned for spring. I’d like to go to Austria with the picks for testing. Next year I hope to hit ice climbing festivals throughout North America.

You can get more information about Howey Tool picks and Howey Tool dry tool holds at http://howeytool.com